Porcelain tile has become the king of modern wall and floor coverings. Its durability, aesthetics, and versatility make it ideal for floors, bathrooms, kitchens, and outdoor spaces. But it's also one of the most demanding materials to install. In this guide, we explain what you need to work with it correctly, from cutting discs to the tools you can rent to make the job easier.

🔍 What is porcelain and why is it so special?

Technical ceramics fired at high temperature

Very low porosity (ideal for humid areas)

High hardness and scratch resistance

Available in large format, imitation wood, marble, cement…

👉 Perfect for demanding renovations, but requires specific tools for handling.

💎 What do you need to cut porcelain tiles?

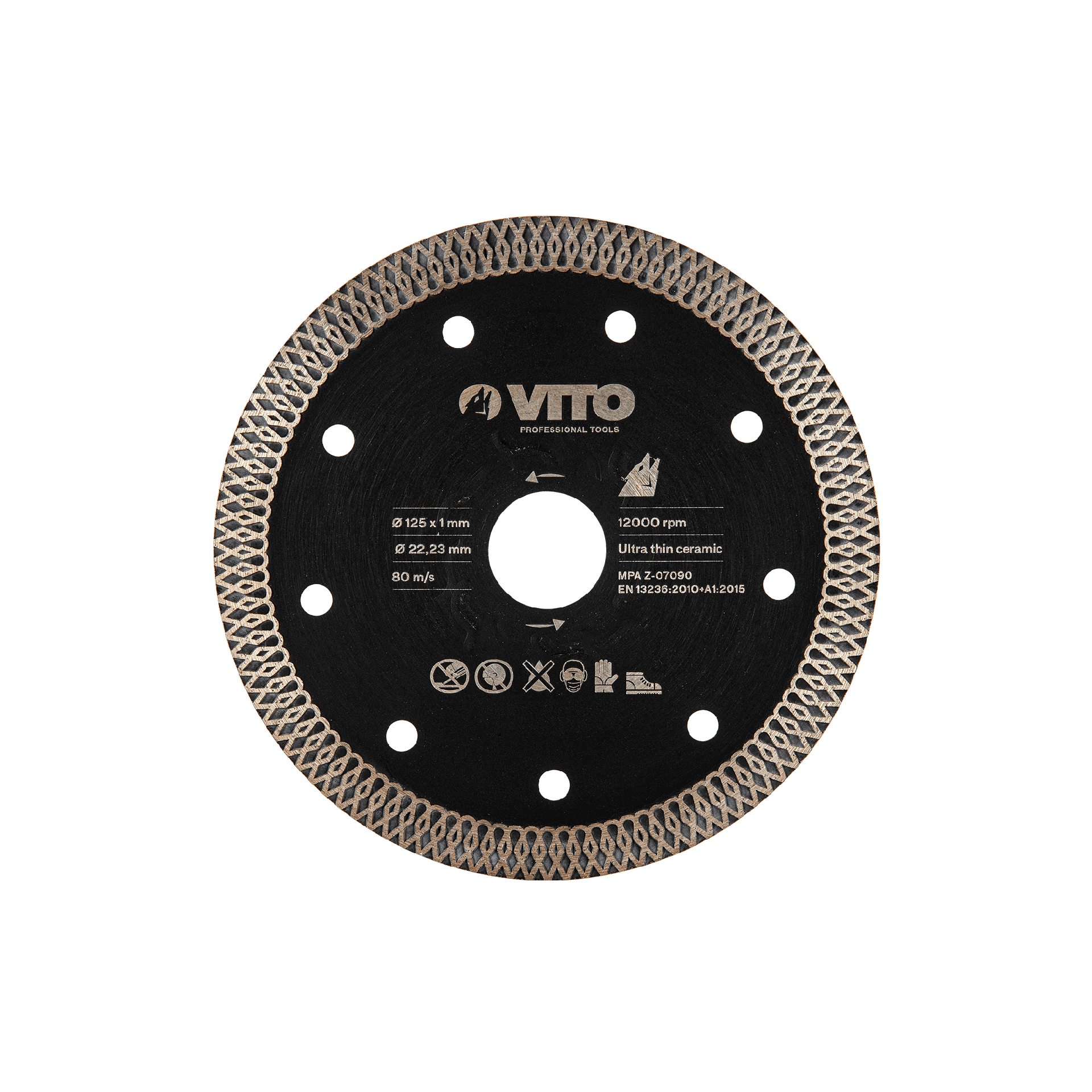

1. Specific diamond discs

Disc Type Wet cutting Dry cutting Main advantages

| Continuous band disc | ✅ | ❌ | Fine cut, no chipping |

| Extra-thin turbo disc | ✅ | ✅ | Fast, good cooling |

| Segmented disc | ❌ | ✅ | For less delicate materials only |

🛒 Available in our shop: grinder and bench cutting discs from 115 mm to 300 mm.

2. Cutting tools

Refrigerated cutting table: Ideal for long and precise cuts

Grinder: Useful for quick cuts and adjustments on site

Professional manual cutter: for straight cuts in thin pieces

🔧 Don't have a cutting table? You can rent one by the day or week from our shop.

🔗 Rent your cutting table here 🔗 View available grinders

Practical tips for working with porcelain

Always use discs specifically designed for porcelain tiles.

When cutting dry, take breaks to avoid overheating.

Mark the cut clearly before making the cut.

Wear gloves, goggles and a mask: ceramic dust is abrasive

If the disc stops cutting properly, it may be dull: clean it or replace it.

♻️ Did you know that some porcelain tiles are made with recycled materials?

Some manufacturers use recycled porcelain (such as sanitary ware or ceramic scraps) and technical resins to create sustainable tiles. These materials can vary in density and performance, making it even more important to use high-quality cutting discs and perform test cuts.

🧲 Complementary tools for a perfect installation

Besides cutting, laying porcelain tiles requires precision and care. These tools are gaining popularity due to their effectiveness:

✅ Suction cups for handling

Manual suction cupsThey allow you to move large pieces without damaging them or soiling the back.

Vibrating suction cup: helps to seat the tile onto the adhesive, eliminating air bubbles and improving grip.

👉 Especially useful in large formats or technical porcelain.

✨ Micro-diamond resin discs

They are used to refine edges, perfect cutouts, or remove small splinters after cutting.

Ideal for visible finishes, corners, countertops or areas where the cut is exposed.

🛒 Available in fine, medium and coarse grain depending on the desired finish.

🛍️ What do we offer in our store?

Diamond discs for dry and wet cutting

Tools for rent: cutting tables, angle grinders, manual cutters

Manual and vibrating suction cups

Resin finishing discs

Accessories: guides, templates, drill bits, masks

👉 Everything you need to install porcelain tiles like a pro, even if it's your first time.